|

Datos del producto:

|

| Temperatura máxima de funcionamiento: | ≥ 1550 | Característica de endurecimiento: | El endurecimiento es muy rápido |

|---|---|---|---|

| Resistencia a la flexión MPa: | 6 | Módulo de la ruptura: | 5 a 12 MPa |

| Paquete de transporte: | 25 kg/bolsa | Temperatura de trabajo: | 1800 ℃ |

| Ventaja: | Operar con convicción | Densidad de volumen: | 2.6 |

| Temperatura de servicio: | 1000°C a 1800°C | Origen: | ZHENGZHOU |

| Tipo de ladrillo: | Arcillas refractarias de fundición | palabra clave: | polvo de K90 refractario |

| Tiempo de fijación: | 4-6 horas | Cambio de línea permanente: | -0,15 ~ 0% |

| Tiempo de curado: | 24 horas | ||

| Resaltar: | cemento refractario de alta alúmina,cemento refractario para hormigón Ca50,cemento de aluminato de calcio Ca70 |

||

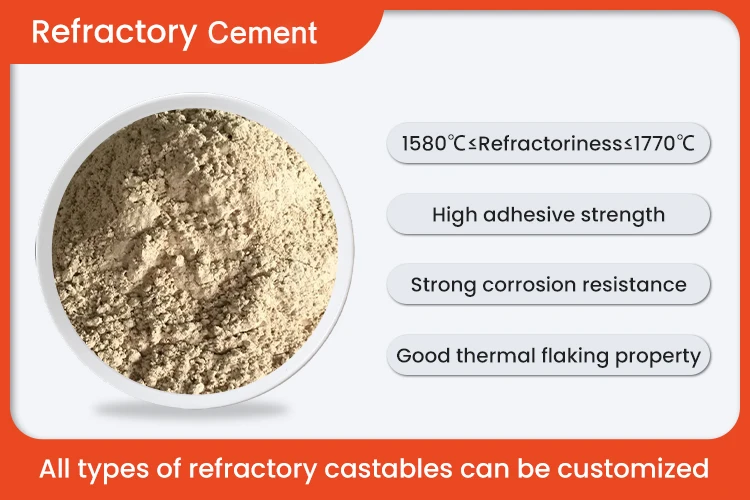

Cemento refractario de alta alumina Introducción:

El cemento de alta alumina (anteriormente llamado cemento de bauxita) es un tipo de cemento hidráulico de molienda con un contenido de clínquer de aproximadamente el 50% de alumina y tiene aluminato de calcio como material principal,que también se llama cemento refractario, que se puede hacer a bajo cemento alta alumina fundible para construir o reparar todo tipo de hornos y hornos para el aislamiento térmico o resistencia a la erosión ácida con alta resistencia.

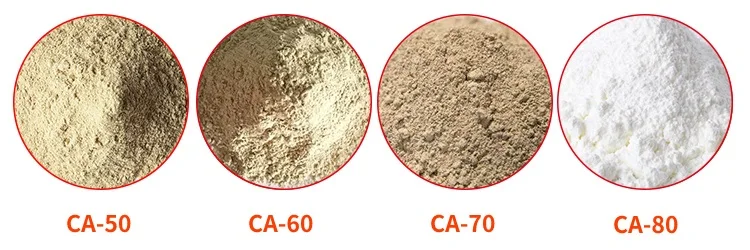

De acuerdo con los diferentes contenidos de Al2O3, pueden tener tipos totalmente diferentes:CA50,CA60,CA70 y CA80.CA-50, CA-70, CA-80, el contenido de alumina es superior al 48%, 68% y 77% respectivamente.Su refractividad es superior a 1650°CLa temperatura de uso puede alcanzar los 1800°C y el contenido de impurezas es inferior al de otros cimentos comunes.

Cemento refractario de alta alumina Características y ventajas:

1. Alta refractividad, alta refractividad bajo carga.

2Alta densidad, baja porosidad.

3Buena resistencia a las escorias y a la corrosión.

4Alta resistencia y resistencia al desgaste.

5- Buena resistencia a las escamas.

6Buena estabilidad térmica.

7. Resistencia de limpieza

8Buena fuerza caliente.

Aplicación de cemento refractario de alta alumina:

1- hornos de la industria metalúrgica, hornos de tratamiento térmico.

2- Horno de incineración de basura, horno de lecho fluidizado de recirculación.

3- hornos de la industria química y de la construcción.

El aluminato de calcio CA-70/80 se utiliza para la fabricación de materiales refractarios de cemento de baja propiedad, refractarios de fundición o refractarios a granel sin forma, que se utilizan a alta temperatura, alta presión,y reducción de la condiciónTambién es un aglutinante de alta calidad de fundición refractaria, que se aplica ampliamente en la industria química, la industria metalúrgica, el material de construcción, la industria petrolera, la industria cerámica, etc.

| Producto | Los demás: | Los demás: | Los demás elementos | Los demás elementos | El CA-80 | |

| Composición química (%) | Al2O3 | 64 a 66 años | 67 a 69 | 69 a 71 años | 73 a 75 años | 77-80 años |

| CaO | 32 a 34 años | 29 a 31 | 27 a 29 | 23 y 25 | 18 a 20 años | |

| SiO2 | 1.8 | 1.2 | 0.3 | 0.3 | 0.3 | |

| Fe2O3 | 0.6 | 0.6 | 0.3 | 0.3 | 0.3 | |

| Superficie específica (cm2/g) | 4500 | 4500 | 5000 | 5500 | 7000 | |

| Tiempo de ajuste (h:min) | Configuración inicial (min) | 0:40 | 0:40 | 0:40 | 0:45 | 0:45 |

| Configuración final (min) | 8:00 | 8:00 | 10:00 | 10:00 | 10:00 | |

| Modulo de ruptura en frío (MPa) | 24 horas | 6.0 minutos | 6.0 minutos | 6.0 minutos | 6.0 minutos | 5.0 minutos |

| 72 horas | 8.0 minutos | 8.0 minutos | 8.0 minutos | 8.0 minutos | 6.0 minutos | |

| Resistencia al aplastamiento en frío (Mpa) | 24 horas | 45.0 minutos | 45.0 minutos | 45.0 minutos | 45.0 minutos | 35.0 minutos |

| 72 horas | 70.0 minutos | 70.0 minutos | 70.0 minutos | 70.0 minutos | 60.0 minutos | |

| Refractabilidad (°C) | 1680 | 1710 | 1730 | 1750 | 1770 | |

Persona de Contacto: Mr. Pika

Teléfono: 86-13838387996

Fax: 86-0371-56010932